Optimizing a bioprocess for the production of an H2/CH4 (biohythane) mixture from household waste

Project details

- Main leader : Ademe - INRA - Trifyl

- Type of initiative :

- Périmètre : Occitanie

- Localisation : 102 Avenue des Etangs - Narbonne - 11100

- Date de début : octobre 2014

- Date de fin : octobre 2017

Economy circular topics

- Recycling

- Sustainable procurement

- Extending useful service life

- Responsible consumption

- Functional service economy

- Industrial and regional ecology

- Eco-design

Today, a growing amount of household and similar waste is being produced. Unless management practices change, such an increase in the volume of waste collected will pose many problems related to a lack of space for its storage, and will have a negative impact on the environment. Among the possible solutions, methanation is a widely developed and proven technology for converting organic matter from waste into energy in the form of methane (or CH4).

In recent years, there has also been increasing interest in the production of hydrogen (or H2), which is considered another key driver of the energy transition. This is because hydrogen has a higher heating potential (120 kJ/g) than methane (50 kJ/g) and the only compound resulting from its combustion is water, making it a product of choice for the transport sector.

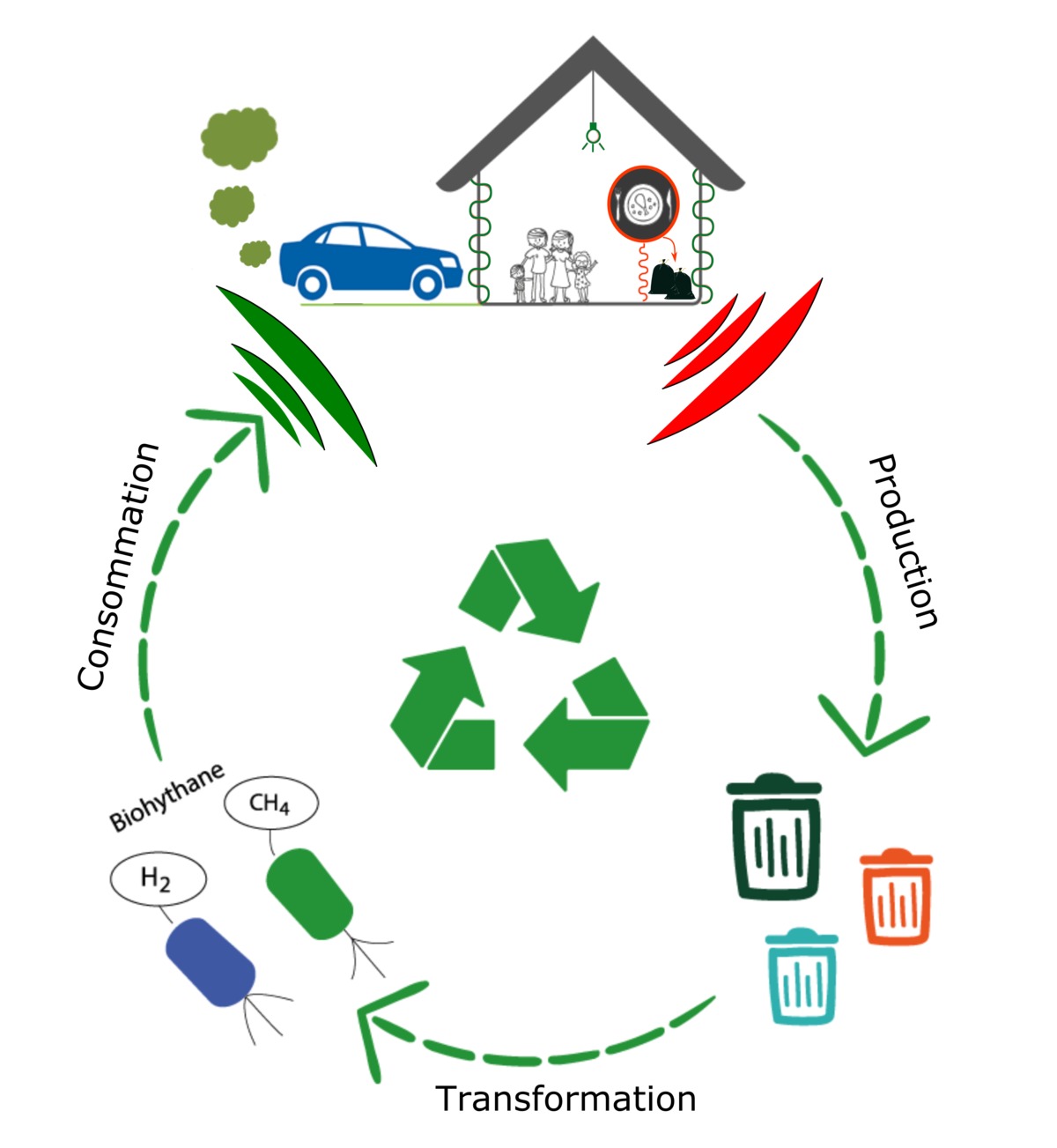

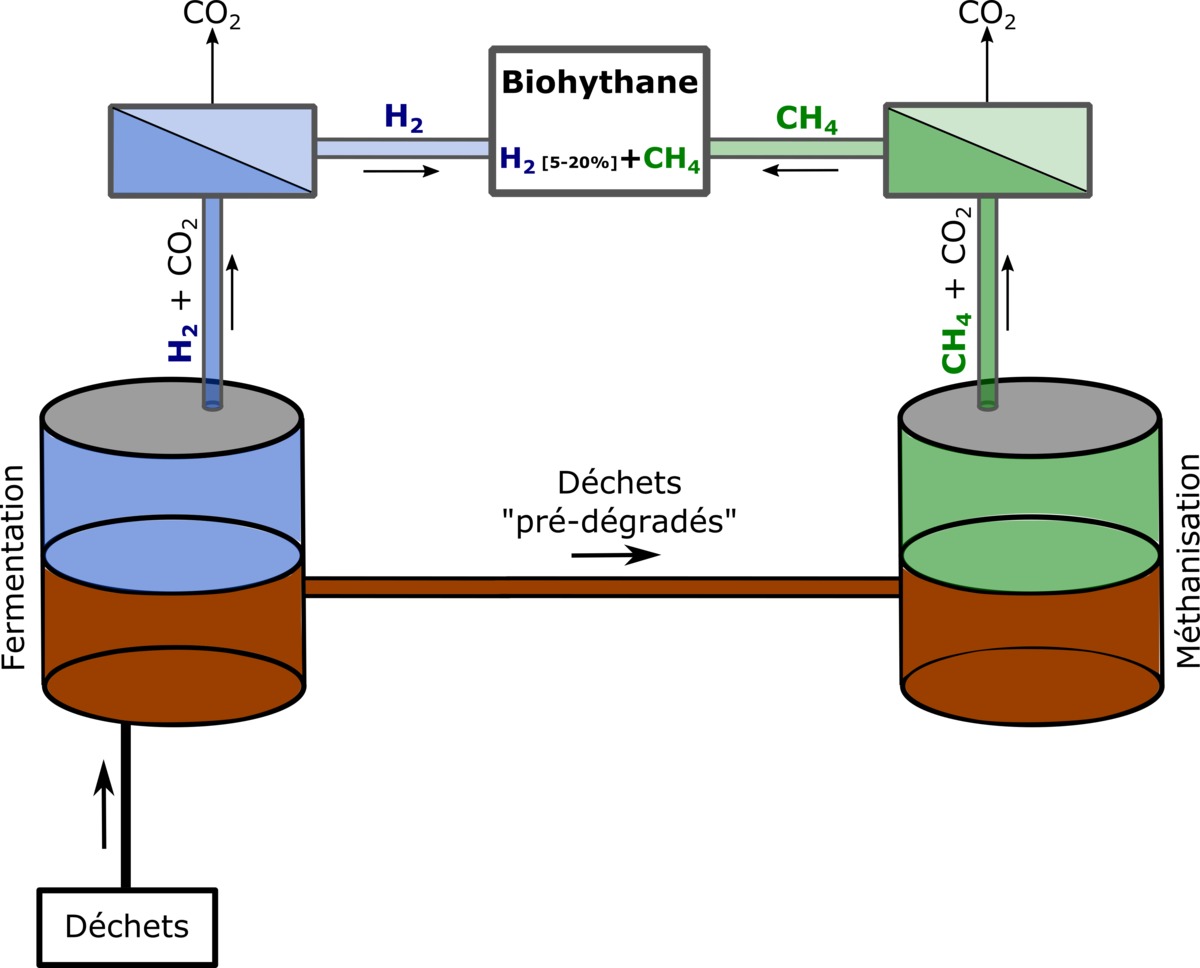

In addition, hydrogen can be added to the methane at a rate of between 5 and 20% to form a mixture called Hythane® which has a lower environmental impact than pure methane if used as a fuel. The advantage of this mixture is that it can be produced biologically (biohythane) using specific microbial communities via a two-stage process. In a reactor, some of the organic matter from the waste is decomposed by bacteria, to produce hydrogen (the fermentation stage). In a second reactor, another microbial community then completes the decomposition of the organic matter and generates methane (the methanation stage) to produce the desired mixture: biohythane.

In order to improve the recovery of household waste, Trifyl (a local syndicate for the treatment of household and similar waste in the Tarn department) has worked with the French National Institute of Agronomic Research (Institut National de Recherche Agronomique - INRA) in Narbonne and the Environment and Energy Management Agency (Agence De l’Environnement et de la Maitrise de l’Énergie - ADEME) on a research thesis whose aim was to improve and optimize a bioprocess for the production of an H2/CH4 mixture (biohythane) from household waste .

Qualitative benefits

Today in France, there is a strong impetus to reduce the storage of household and similar waste, and improve the way it is recovered in order to create a circular economy based on respect for the environment. The increasing amount of waste produced per capita, the pollution caused by storing it and the scarcity of raw materials are all major issues that are driving us to change our behaviour and the way we consume.

Recovering energy from household waste produced biologically is a promising field. The production of biohythane (composed of 5-20% of hydrogen and methane) from domestic waste via a two-stage process is a field of research that includes many avenues still to be developed in the long term with a view to using this process on an industrial scale. As far as the production of methane is concerned, the technology is a mature one, with many existing industrial processes. However more detailed examination of dark fermentation (to produce hydrogen) is required to better understand this process and find the optimal operating conditions for improving the hydrogen yield.

The move up from laboratory scale to a pilot and finally to industrial scale is based on a better understanding of the key mechanisms at work in this process in order to enable subsequent optimization. The key parameters related to Trifyl’s industrial context were mainly centred around resources available on the Trifyl site to carry out the dark fermentation process, namely the organic fraction of household waste collected by Trifyl and the leachate (wastewater) which both contributes to the microbial community producing hydrogen and provides an essential supply of water for producing a substantial amount of hydrogen. However, the use of these resources specific to Trifyl has led to several issues affecting this study. Hydrogen production can be limited by elements contained in the leachate which, by accumulating within the medium, can negatively impact the production of hydrogen. In this context, it was therefore necessary to first focus on the main limits of dark fermentation. When using organic waste made up partly of food waste (44%), a molecule called ammonia (NH3), resulting from the degradation of proteins, has regularly been reported as highly problematic. During this thesis it was therefore necessary to study the impact on our fermentation process. In addition, the leachate has a high concentration of ions which can also disturb the dark fermentation process. It was therefore essential to examine the consequences of this factor on the production of hydrogen.

In opposition to the parameters negatively impacting the production of hydrogen, an improvement in hydrogen yield was obtained by studying various parameters, either easily adjustable ones such as the amount of water in the medium or the temperature of the medium, or one that are difficult to modify at industrial level (pH, ammonia concentration and substrate characteristic). Overall knowledge of the values that help to intensify the productivity of hydrogen make the industrial-scale process more reliable. Overall, the hydrogen production optimization study has made it possible to improve the stability and robustness of the fermentation reactor in order to promote the economic credibility of such a process.

Finally, to be able to have a biohythane production process on an industrial scale, issues related to changes in scale and more particularly to the design of the reactor have also been carefully studied. The is because the configuration of the reactor can modify certain physico-chemical data such as hydrogen partial pressure and gas/liquid transfer which will potentially lead to a decrease in the hydrogen yield.

The results of these various studies are now used as a basis for the design of a two-stage process with a view to ultimately obtaining industrial production of biohythane.

Areas of activity

- Energy

- Mobility

- Transport

- Recycling

Following the LTE law aimed at reducing the storage of waste and the scarcity of raw materials, household waste is today perceived as a significant resource of materials. This new vision fits perfectly with the move towards a new mode of consumption and functioning based on a more sustainable economy known as the "circular economy".

According to ADEME, the circular economy “aims to change the pattern with respect to the so-called linear economy, by limiting waste of resources and environmental impact and increasing efficiency at all stages of the product economy”. The circular economy therefore aims to minimize the environmental impact of a product, a process or a service from the design stage (ecodesign). This involves responsible consumption, where the consumer is better able to choose what he/she consumes, taking into account the environmental impact of the product's life cycle. A desire to extend the life of a product by repairing it, or by buying second-hand products is an important factor. At the end of the product's life, the raw materials can also be recycled or recovered to create a new product to market.

Sustainable waste management must therefore include:

- ways of recovering materials via recycling processes,

- ways of recovering heat for energy production,

- biological recovery means, using micro-organisms to transform matter into fertilizer (compost) or energy (biogas).

The recovery sector must be appropriate to the type of waste contained in household and similar waste. Material recovery mainly concerns recyclable waste and waste electrical and electronic equipment (WEEE), while thermal and biological recovery is better suited to residual waste, and to green, organic waste respectively. In this context, especially, a great deal of research is being carried out with the aim of improving the recovery of suitable waste by biological means.

Resources

- Waste

- Biowaste

- Renewable energies

- Biogas

- Methanation

Pillar(s) of the circular economy

- Recycling

- Sustainable procurement

Technical resources

This research was done through a thesis. During this thesis, the experimental studies were carried out at the Environmental Biotechnology Laboratory (LBE) in partnership with Trifyl and under the supervision of ADEME.Financers

- Trifyl

- ADEME